Browsing the World of Fasteners and Machining: Methods for Accuracy and Speed

In the detailed realm of bolts and machining, the quest for accuracy and speed is a continuous challenge that requires thorough interest to information and strategic planning. From comprehending the varied array of fastener kinds to picking optimal products that can hold up against rigorous needs, each action in the procedure plays a critical function in attaining the desired result. Accuracy machining strategies further raise the intricacy of this craft, requiring a delicate balance in between technological experience and innovative methods. As we dive into the techniques that can boost both rate and efficiency in this domain, the interplay between quality assurance procedures and functional quality arises as a vital centerpiece.

Understanding Fastener Kind

When selecting fasteners for a task, understanding the numerous types available is critical for guaranteeing optimum performance and dependability. Screws are used with nuts to hold materials with each other, while screws are functional bolts that can be made use of with or without a nut, depending on the application. Washers are crucial for distributing the tons of the bolt and preventing damage to the product being fastened.

Choosing the Right Products

Recognizing the importance of choosing the ideal products is paramount in guaranteeing the ideal performance and dependability of the picked bolt kinds talked about previously. When it involves bolts and machining applications, the material selection plays a crucial role in figuring out the general toughness, longevity, corrosion resistance, and compatibility with the intended environment. Different materials offer varying properties that can significantly impact the performance of the fasteners.

Common materials used for bolts consist of steel, stainless steel, aluminum, titanium, and brass, each having its one-of-a-kind strengths and weak points. Steel is renowned for its high stamina and resilience, making it ideal for a broad array of applications. Choosing the right product entails thinking about variables such as stamina requirements, environmental problems, and budget restrictions to ensure the preferred efficiency and longevity of the fasteners.

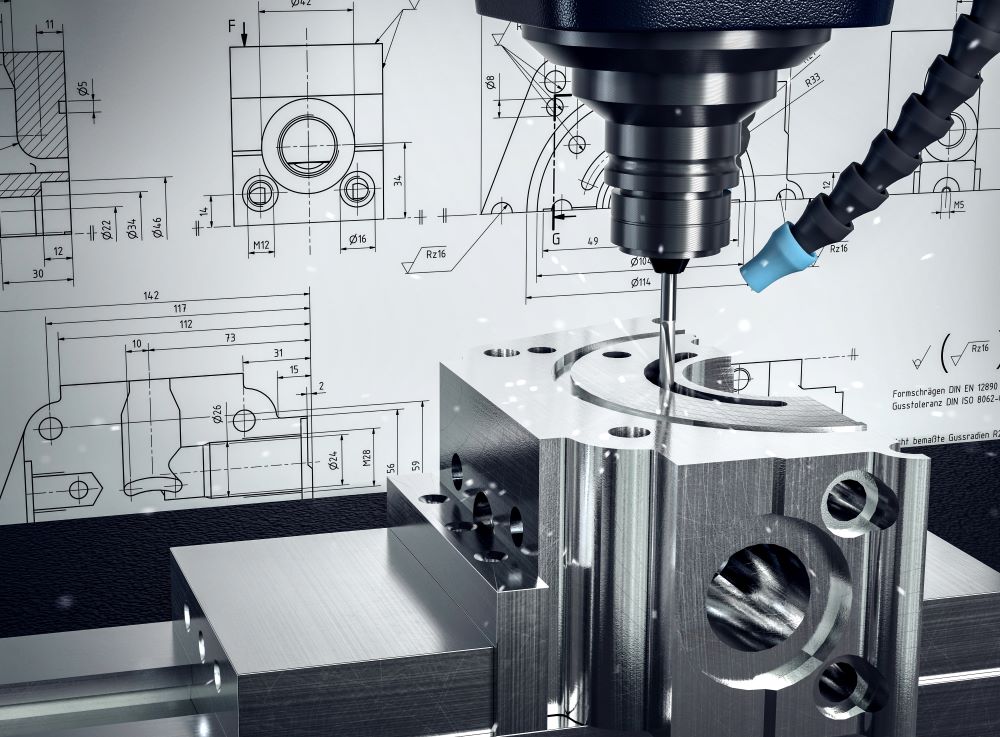

Accuracy Machining Techniques

Along with CNC machining, other accuracy techniques like grinding, turning, milling, and exploration play important duties in fastener production. Grinding helps accomplish fine surface area finishes and hop over to these guys tight dimensional resistances, while transforming is commonly used to produce round parts with accurate sizes. Milling and drilling operations are necessary for shaping and creating openings in bolts, ensuring they satisfy precise requirements and function properly.

Enhancing Rate and Performance

To maximize bolt production processes, it is essential to enhance operations and apply effective strategies that match accuracy machining methods. Automated systems can take care of repeated Recommended Site jobs with precision and speed, permitting workers to concentrate on even more complex and value-added tasks. By combining these methods, manufacturers can accomplish an equilibrium between rate and precision, eventually boosting their competitive edge in the bolt market.

Quality Assurance Procedures

Implementing extensive quality assurance measures is vital in guaranteeing the dependability and uniformity of fastener products in the production procedure. Quality control measures include numerous phases, starting from the option of raw materials to the final assessment of the ended up fasteners. One fundamental element of quality assurance is performing complete material inspections to validate conformity with specifications. This involves evaluating aspects such as material structure, stamina, and toughness to ensure that the fasteners satisfy industry standards. Additionally, checking the machining refines is necessary to maintain dimensional precision and surface finish top quality. Making use of sophisticated innovation, such as computerized examination systems and accuracy measuring tools, can enhance the accuracy and performance of quality assurance procedures.

Regular calibration of devices and machinery is imperative to preserve uniformity in production and make sure that bolts meet the necessary resistances. Executing rigorous protocols for determining and addressing flaws or non-conformities is vital in stopping substandard items from getting in the market. By developing an extensive high quality control structure, manufacturers can support the track record of their brand and deliver fasteners that satisfy the greatest requirements of efficiency and longevity.

Conclusion

In the intricate realm of fasteners and machining, the quest for precision and rate is a continuous difficulty that requires careful focus to information and calculated preparation. When it comes to fasteners and machining applications, the material choice plays an important function in figuring out the general stamina, sturdiness, rust resistance, visite site and compatibility with the designated environment. Precision machining entails numerous innovative techniques that guarantee the tight tolerances and requirements needed for bolts.In addition to CNC machining, various other accuracy methods like grinding, turning, milling, and drilling play essential duties in fastener production.To enhance fastener production procedures, it is necessary to enhance operations and apply reliable methods that complement accuracy machining methods.

Comments on “The Duty of Fasteners and Machining in High-Quality Product Style”